Welcome to

at Aivarex!

We produce with green energy.

WHO ARE WE?

Masters of stainless pipe parts.

As a Hungarian family-owned company, Aivarex manufactures machine parts from stainless steel with decades of professional experience. Our customers are prestigious, market-leading players in the food industry throughout Europe, whose high-level technological expectations we are always proud to meet.

And why with green energy? Because from the beginning, it is important for us to leave as small an ecological footprint as possible as a manufacturing company. That is why we cool and heat both of our locations in Hungary with ground-source heat pumps, we have significant solar panel capacity in both locations, and we also like to use electric vehicles.

OUR PRODUCTS

Everything that is stainless.

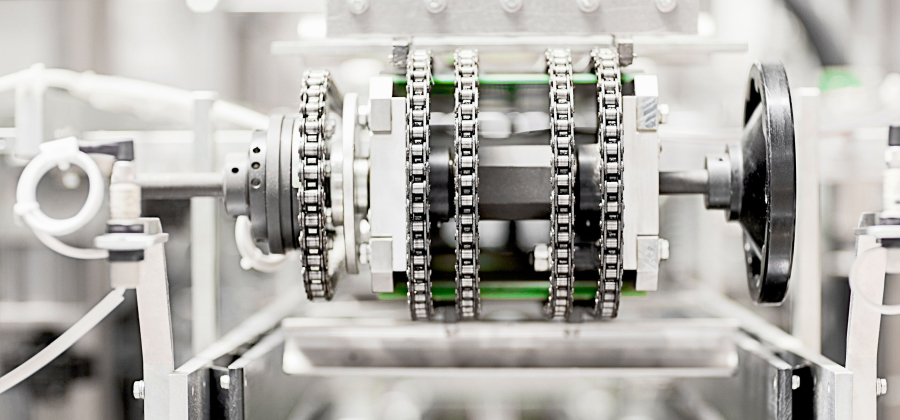

PIPE COMPONENTS

Bending. Pipe end machining. AWI welding. These are just some of the key operations with which we produce a wide variety of components for professional food industry equipment. We can realize almost any idea from stainless steel - even with extreme shape, surface or dimensional tolerances.

SPRAYING OF GLASS BEADS

Our surface treatment process, mixed with corundum or pure glass beads, gives a uniform, elegant surface to all products. Removes running colors from welding seams and minor surface scratches. It is often used for pieces whose sanding is difficult or does not lead to satisfactory results. We also accept paid work!

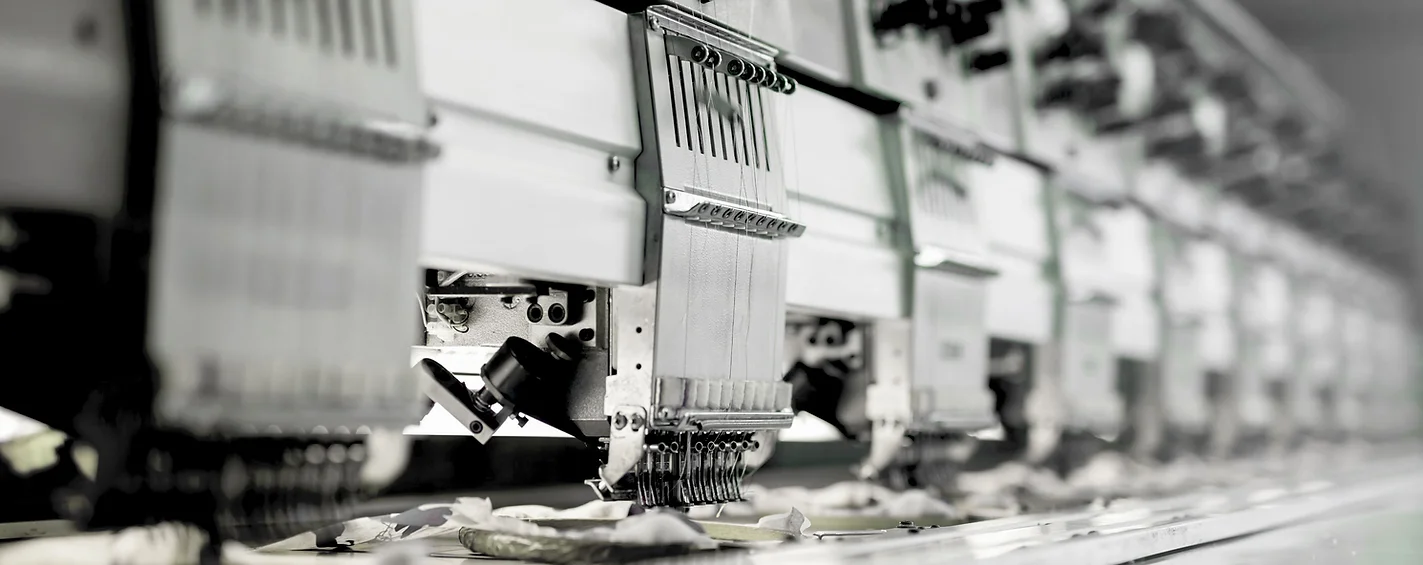

UNIQUE PRODUCTS

You know how it is. At first, only our friends asked: could you make this clothes hanger out of stainless steel? Sure, we found out. Since then, our Special business has been manufacturing veterinary furniture, cemetery wreath holders, restaurant napkin dispensers, safety barriers, studio speaker stands with great love and experience.